In the pursuit of efficient, safe and practical storage space solutions, steel lockers have become the first choice for many places (such as schools, offices, gyms, etc.) because of their durability, easy cleaning and maintenance.

However, there are some common misunderstandings in the purchase and use of steel lockers, which, if not corrected, may affect the actual utility and user experience of the lockers.

Mistake 1: Assuming “All Steel Lockers Are Rust-Proof”

The Reality

Not all steel is created equal. While steel lockers are inherently durable, materials like cold-rolled steel or standard 304 stainless steel can fail rapidly in harsh environments.

Case Study:

A Texas coastal school purchased 304 stainless steel lockers, expecting decades of service. Within 6 months, pitting corrosion appeared due to airborne salt particles. The repair cost exceeded $80,000.

The Fix: Material Science Matters

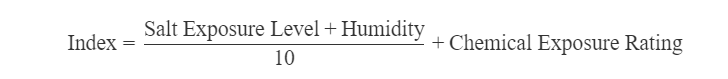

Environmental Corrosion Index:

Index < 10: Powder-coated carbon steel suffices.

Index > 15: Use 316L stainless steel with epoxy-polyester hybrid coating.

Maintenance Protocol:

Inspect weld seams quarterly for sealant gaps.

Apply anti-corrosion spray (pH-neutral) every 90 days in high-risk zones.

Mistake 2: Prioritizing Size Over Space Efficiency

The Reality

Oversized lockers waste 37% of floor space on average while increasing manufacturing costs by 22%.

The Fix: Optimize 3D Utilization

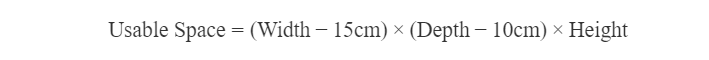

Effective Volume Formula:

(15cm/10cm reserved for door swing and access)

Modular Design:

Combine 200L base units with overhead compartments for vertical storage.

Mistake 3: Neglecting Structural Anchoring

The Reality

Improper installation can turn lockers into safety hazards. In 2023, OSHA reported 17 injuries caused by unanchored lockers tipping over.

The Fix: Engineering-Grade Installation

Anchoring Force Calculation:

(Multiply by 2.0 in seismic zones)

Precision Tools:

Use laser levels to ensure tilt < 0.5 degrees.

Install seismic bracing kits (compliant with IBC 2021).

Mistake 4: Overestimating Digital Lock Reliability

The Reality

Advanced locks can backfire:

RFID locks fail 23% of the time in sub-zero temperatures.

Biometric systems struggle in dusty environments (error rate: 15%).

The Fix: Match Technology to Environment

| Scenario | Recommended Lock | Avoid |

|---|---|---|

| High EMI Areas | Mechanical Key Locks | RFID/Bluetooth Locks |

| Extreme Temperatures | Mechanical Combination Locks | Battery-Powered Electronic Locks |

| Government Facilities | Biometric + Physical Key Hybrid | Cloud-Dependent Systems |

Mistake 5: Underestimating Maintenance Complexity

The Reality

Wiping surfaces isn’t enough. Improper cleaning agents reduce coating lifespan by 63%.

The Fix: Data-Driven Maintenance

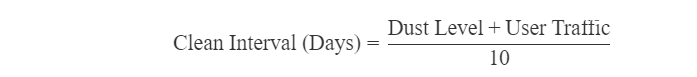

Cleaning Frequency Formula:

Result > 10: Deep clean weekly with microfiber and neutral detergent.

Coating Repair Kit:

pH test strips (target: 5.5–7.5).

Nano-ceramic repair spray for scratches.

Conclusion:

In summary, when purchasing and using steel lockers, you should avoid the above misunderstandings to avoid frequent problems during use and increased costs in the later stage.